Gemco

7.5HP Q-Type Pellet Machine (Gasoline Engine)

7.5HP Q-Type Pellet Machine (Gasoline Engine)

Couldn't load pickup availability

- Description

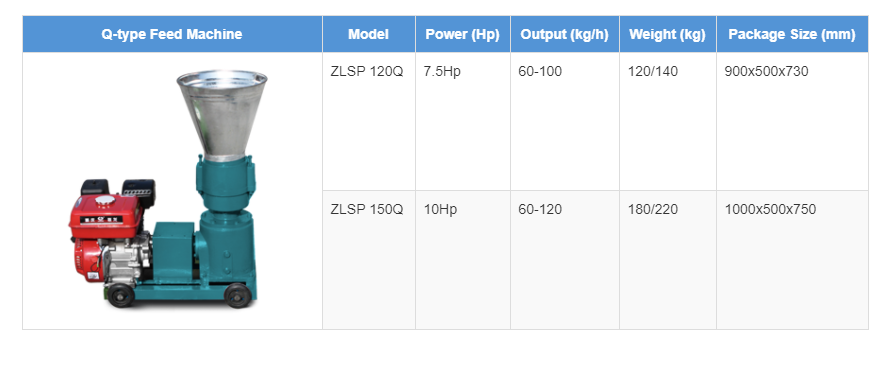

| Type | ZLSP 120Q |

|---|---|

| Driven by | Gasoline Engine |

| Power | 7.5Hp |

| Output | 60-100 kg/h |

| Weight | 120/140 kg |

| Package Size | 900x500x730 cm |

| Material | Corn, maize, wheat bran, rice, beans, leftover etc. |

| Application | Widely used for making poultry, cattle, cow, chicken (broiler or layer), fish, pig, sheep/goat and other kinds of animal feed pellets. |

This feed mill equipment is widely used for making fish feed, cattle feed, pig feed, and chicken feed. So some people also call it fish feed machine or cattle / chicken feed making machine. Actually, it has a much wider application field such as making feed for cattle, chicken (broiler and layer), pig, duck and many other livestock. The diameter and size of final pellets is adjustable. You can decide the size and ingredient depending on the eating habits of each animal. If you raw materials are mainly fodder grass or alfalfa hay, have a look at how to make grass pellets for feed.

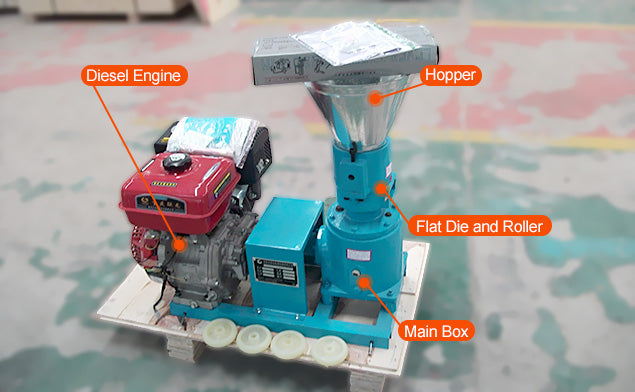

This small animal feed machine is driven by gasoline engine. It is movable and convenient to use in the open air without electricity. Flat die poultry feed making machines have small size, simple structure, low noise and are very easy to operate even if for new beginners. It is adequate for home use and individual use.

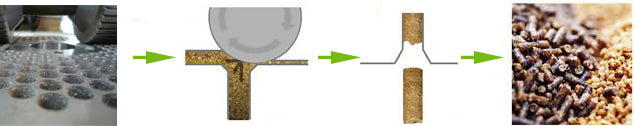

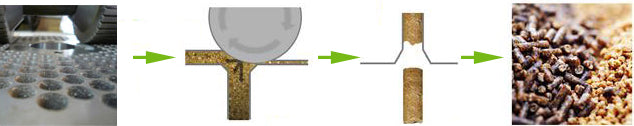

The gear box drives the main shaft and the die and have friction with the roller, and the resulting friction temperature (between the die roll and the die) can reach about 80°C. The material is then through the high temperature action, under the action of the press roll, through the hole in the die plate, and forms high quality pellets and discharged out from the outlet. Please note the length of the pellets can be adjusted by the position of the cutter bit.

The flat die equipped with the mini poultry feed machine is processed and manufactured based on the data from experiments of a large number of raw materials. Most of the raw materials can have a better effects to make pellets. However, if there are particle dust and low rate of pelletizing of your raw materials, in order to get the BEST pelletizing effects, please adjust the compression ratio according to the your raw material.

For mini poultry feed machine price, please contact us directly to get the full detailed specificatsion and costs of small poultry feed mill machinery. In addition to gasoline, we also have motor driven, diesel and PTO powered mini animal feed mill machine to fit your needs!

Note: Items are shipped directly from manufactuer & lead times can vary. Typical lead time is 8-10 weeks.

Share